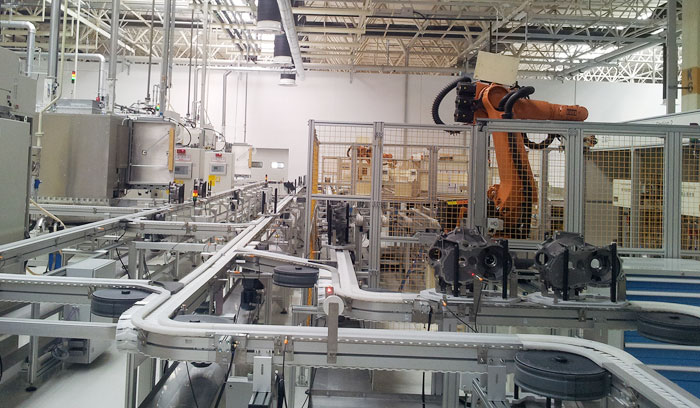

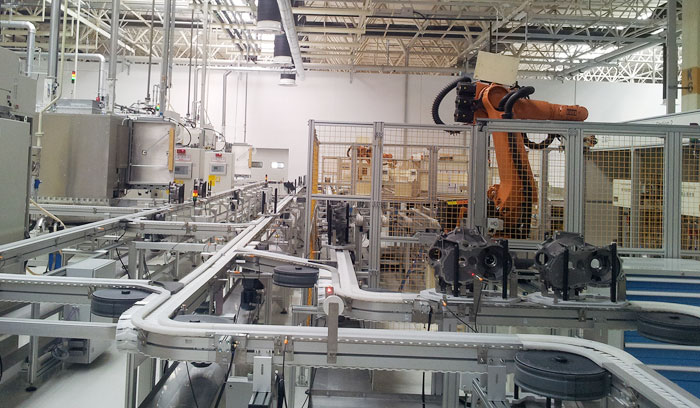

Heavy-duty friction roller line refers to changing the nature and design of the roller line to improve its wear resistance, corrosion resistance and high temperature resistance, so as to extend the service life of the roller line and improve its performance. At present, friction roller lines are mainly used in mechanical transmission systems, rail transit, wind power generation, aerospace and other fields, assuming an important transmission and support role. However, because the friction roller line will be affected by the external environment during use, such as friction, wear, corrosion and high temperature, it will lead to reduced performance and shortened life. Therefore, the research and development of heavy load friction roller line has important engineering application value.

In the development process of heavy-duty friction roller line, there are several key technologies:

1. Research and development of new materials: Select new materials that are resistant to wear, corrosion and high temperature, such as high-hardness alloys, ceramic materials and nanomaterials, etc., for the manufacture of key components of friction roller lines to improve their service life and wear resistance.

2. Surface treatment technology: The use of physical, chemical and heat treatment and other surface treatment technology to form ceramic coatings, films and nitriding layers, etc., to improve the wear resistance and corrosion resistance of the friction roller line.

3. Structural design optimization: By optimizing the structure and parameters of the roller line, such as reducing the number of contact points, increasing the number of rollers, changing the distance and Angle of rollers, etc., to improve the transmission efficiency and carrying capacity of the friction roller line.

4. Lubrication technology: The development of new lubricants, such as nano lubricants, solid lubricants and high temperature lubricants, for the lubrication of friction roller lines and reduce friction loss, reduce energy consumption and heat generation.

5. Simulation and test technology: Establish a simulation model of the friction roller line, and conduct a variety of mechanical properties tests, such as load capacity, wear performance, friction coefficient and friction heat, for evaluating the feasibility and performance of new materials and structural design.

Through the research and application of the above key technologies, the important characteristics and performance improvement of heavy-duty friction roller lines can be realized. This will improve the efficiency of the transmission system, reduce energy consumption, extend equipment life and reduce maintenance costs have important practical application value. In future studies, it is necessary to further explore new materials and preparation technologies, develop new lubricants and surface treatment technologies, optimize structural design and reduce friction losses to meet the growing engineering needs and challenges. The research of heavy-duty friction roller lines will continue to promote the development of driveline technology and contribute to the development of the industrial field.

No. 3, Guangda Road, Zhitang Industrial Park, Changshu City