The structure design of friction roller is a design process of reducing the friction force of roller on wire and improving the economic performance of wire through reasonable configuration and layout of roller line. The heavy load of the friction roller structure design refers to the improvement and optimization of the friction roller structure according to different use conditions and requirements to meet the needs of higher loads.

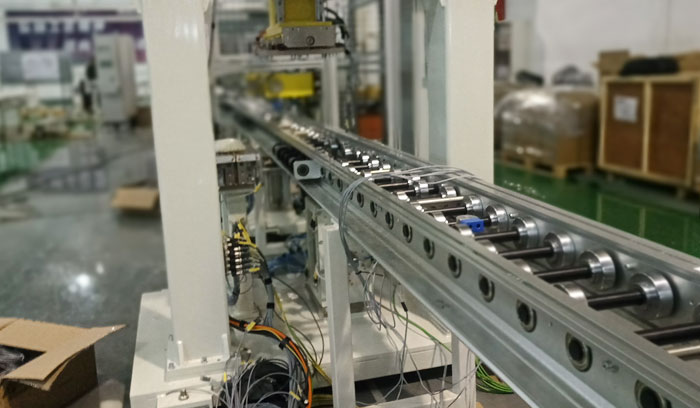

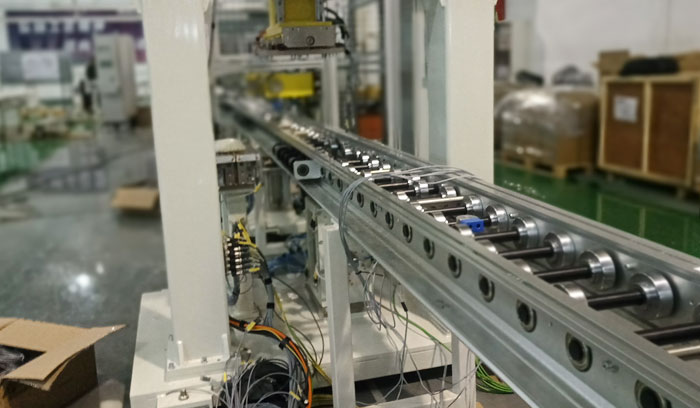

In the design of heavy load friction roller line structure, the first thing to consider is the selection of rollers. The material of the roller should have high strength and hardness and can withstand large loads. Commonly used roller materials are alloy steel, engineering plastics and so on. The second is the shape design of the roller. In order to reduce the friction of the roller on the wire, the contact surface of the roller should be as smooth as possible, and the contact area should be large enough to avoid damage to the wire caused by concentrated force.

In the design of friction roller structure, it is also necessary to consider the layout of the roller and the path of the line. In order to increase the number of rollers and maintain proper spacing, a multistage arrangement or a two-line design can be used. In this way, the supporting force of the roller on the wire can be increased, the friction can be reduced, and the service life and economic performance of the wire can be improved.

In addition, the material selection and structure design of the track are also very important in the design of the heavy load friction roller line structure. The material of the track should have high hardness and wear resistance to reduce the wear and friction of the track surface. At the same time, the structural design of the track should be reasonable to avoid gaps or dead angles, affecting the movement of the roller and the smooth passage of the wire.

In addition to material and structural design, the heavy load design of roller line structure also needs to consider the mechanical properties of the system. Through reasonable mechanical analysis and calculation, the size and material of the roller, as well as the maximum load and stress limit of the wire can be determined. The factors considered in the calculation include the roller load distribution, the interaction between the rollers, the contact mode between the rollers and the wire, etc.

In addition, the design of heavy-duty friction roller line structure also needs to consider the protection and maintenance of wire. Wire in the process of use may be affected by the external environment, such as dust, humidity, etc., so it is necessary to take appropriate protective measures, including the use of dust cover, installing sealing rings. At the same time, regular maintenance and inspection are also necessary to ensure the normal operation and service life of the wire and roller.

In summary, the design of heavy-duty friction roller structure is a design process to improve the load capacity and economic performance of friction roller structure by selecting suitable materials, optimizing the shape and layout of the roller, designing reasonable track and calculating mechanical properties, and taking appropriate wire protection and maintenance measures. In practical applications, specific designs and adjustments need to be made according to different use conditions and requirements to meet actual needs.

No. 3, Guangda Road, Zhitang Industrial Park, Changshu City