Synchronous belt transmission line is a kind of mechanical transmission equipment, mainly composed of synchronous belt, gear, motor, transmission line, etc. The conveyor line of the synchronous belt transmits power to the gear through the synchronous belt, and then drives the conveyor line to work through the motion formed by the gear. Among them, the role of the synchronization belt is to convert the power on the gear into mechanical motion to ensure the normal work of the transmission line. Synchronous belt conveyor lines can usually achieve long-distance (generally tens of meters to more than 100 meters) material transportation.

Synchronous belt conveyor line has the advantages of simple structure, smooth transmission, high efficiency, long life, etc., and is widely used in chemical, pharmaceutical, food processing, machinery manufacturing and other fields. The following introduces the composition, working principle, advantages and application of synchronous belt conveyor line in turn.

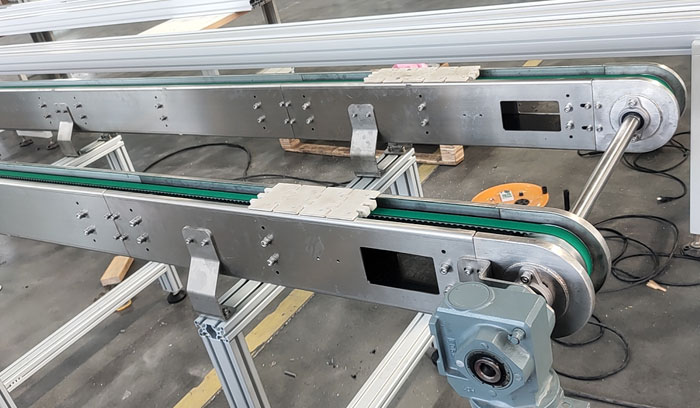

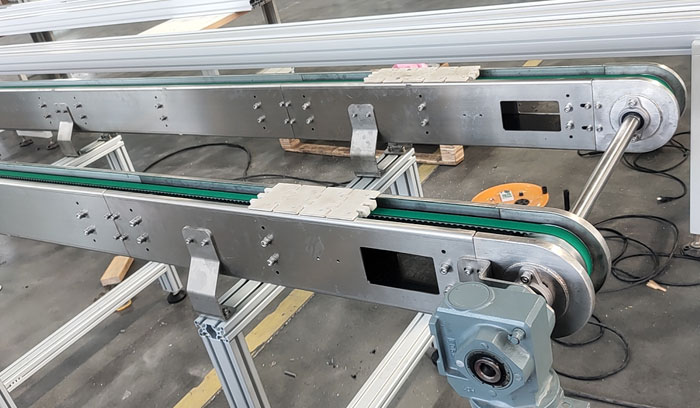

The composition of synchronous belt conveyor line

The main components of the synchronous belt conveyor line are as follows:

1. Synchronous belt: responsible for transferring power to the gear, to ensure that the gear and the transmission line work simultaneously, to achieve the conveying of materials.

2. Transmission gear: Under normal circumstances, the synchronous belt is driven by a pair of gears, the two gears have the same number of teeth, and are respectively connected to the power source and transmission line.

3. Motor: to provide power, the motor of the synchronous belt transmission line is mostly decelerated motor, which plays the role of reducing speed and increasing torque.

4. Conveying line: Conveying the material from the discharge port to the feed port.

5. Bracket: used to fix the entire conveyor line to ensure the stable operation of the equipment.

Working principle of synchronous belt conveyor line

The synchronous belt conveyor line is mainly driven by the synchronous belt and is carried out by the transmission gear. First, the power of the motor is transmitted through the transmission mechanism (usually a reducer) to the transmission gear on one side, and then the transmission gear drives the synchronization belt to rotate. The synchronous belt slides on the outside of the gear, only in contact with the gear at the top of the gear, and the rack is very accurate, so it can accurately transfer power when turning. The gear on the other side of the transmission gear is connected with the transmission line drive device through synchronous transmission, and the transmission line begins to rotate, transferring the material from the discharge port to the feed port, while the material covered by the transmission line naturally slides. Throughout the process, the accuracy of the synchronization belt and gear determines the transmission stability of the equipment, such as the accuracy of the synchronization belt is not high, will lead to vibration at the gear node, affect the normal work of the transmission line, but also shorten the life of the equipment.

No. 3, Guangda Road, Zhitang Industrial Park, Changshu City